fire control panel contract manufacturing

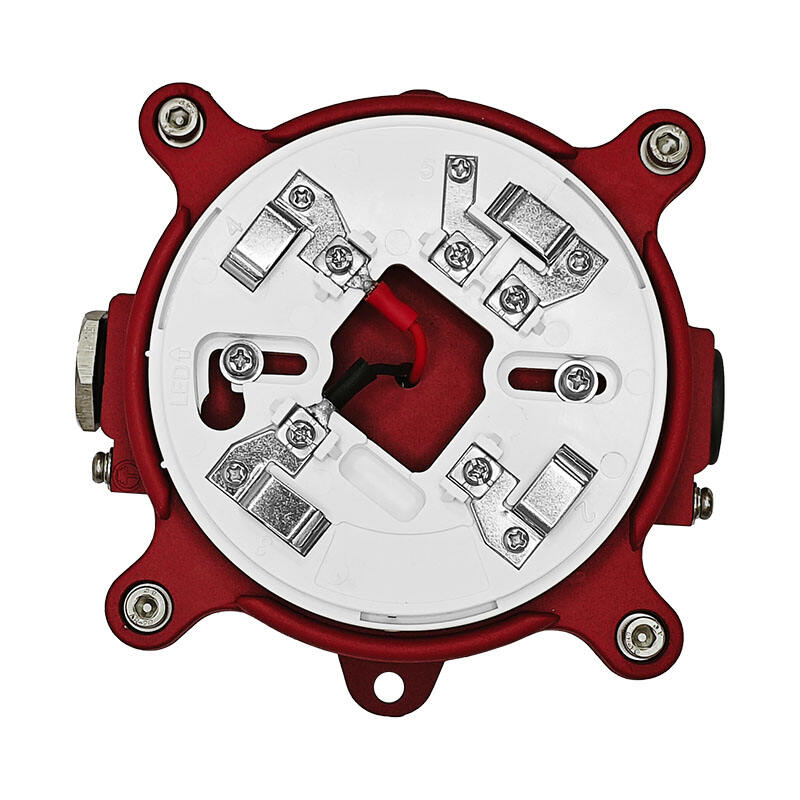

Fire control panel contract manufacturing represents a critical service in the fire safety industry, encompassing the production of sophisticated electronic systems that serve as the central nervous system of building fire protection. These panels are engineered to monitor and control various fire detection devices, including smoke detectors, heat sensors, and manual call points, while managing crucial safety responses such as alarm activation, door releases, and sprinkler systems. Modern fire control panel manufacturing involves advanced printed circuit board assembly, precise electronic component integration, and rigorous quality control processes. Manufacturers employ state-of-the-art surface mount technology (SMT) and through-hole assembly techniques to ensure reliable performance and compliance with international safety standards. The manufacturing process includes comprehensive testing phases, from individual component verification to complete system functionality assessment. These panels are designed to operate 24/7, featuring redundant power supplies, backup batteries, and fail-safe mechanisms. Contract manufacturers specializing in fire control panels must maintain certifications such as ISO 9001 and specific fire safety standards, ensuring their products meet strict regulatory requirements across different markets and applications.