What sets explosion proof heat detectors apart from standard models is mainly their build quality and how well they keep dangers contained. These detectors are made using tough materials like stainless steel and various strong metal alloys so nothing inside can spark a fire outside. Regular heat detectors usually come in plastic cases which just don't cut it in dangerous areas. The choice of materials really matters when it comes to containing potential risks. Take pressure differences for example these detectors hold up under stress without breaking down, something critical where explosions might happen. Plus most have special coatings on the surfaces that fight off chemical damage, which makes all the difference in factories and plants where harsh chemicals are part of daily operations.

To work safely in places where explosions could happen, explosion proof detectors need to pass certain certification tests. Standards such as ATEX across Europe and NEC here in America set out exactly what makes a device safe enough for areas with explosive gases or dust. No one should install equipment without proper certification papers showing it meets these requirements. Take Zone 1 rated gear for instance it works best in spots where flammable mixtures tend to form regularly. Getting all this paperwork right matters a lot because without proper certifications from authorities like ATEX or NEC, companies risk putting workers in danger while also facing legal issues down the road. Most industrial sites understand this now and keep strict records on their certified equipment inventory.

Explosion proof detectors really stand out when put through their paces in harsh environments compared to regular models. These units can handle temperatures ranging anywhere between minus 40 degrees Celsius all the way up to plus 70 degrees Celsius, something most standard equipment simply cannot manage. Manufacturers subject them to rigorous testing conditions including sudden environmental changes, constant vibrations, and fluctuating moisture levels – all key concerns in real world industrial operations. Practical field experience shows these detectors consistently perform well even under tough circumstances, which is why they're so widely adopted across dangerous work sites. Their durability makes them an essential tool for keeping workers safe in factories, chemical plants, and other locations where ordinary sensors would quickly give up the ghost.

Looking at safety options for dangerous workplaces, there are basically two different ways to go: intrinsic safety versus explosion proof housing. With intrinsic safety, the idea is to build equipment so it can't generate enough power to start a fire or explosion, even if something goes wrong. That makes these systems great for places where sparks could be deadly. The whole point is keeping energy levels way below what would actually cause trouble. On the other side of things, explosion proof housing works differently. These systems contain any potential explosions inside their casing before they can spread out into the air around them. Most experienced engineers will tell anyone who asks that picking one method over the other really depends on what kind of work environment we're talking about and how thorough our safety evaluations have been done beforehand.

Explosion proof heat detectors can handle tough environments, something clear from their IP66 certification. The rating means they won't let dust get inside and they stand up pretty well against heavy water spray too. This matters a lot when these devices need to work properly even when things get rough around them. These detectors come with set temperature limits so they keep working right no matter if temperatures swing between scorching hot days or freezing nights. Protection against environmental issues helps avoid problems down the road when equipment fails unexpectedly. Following those IP standards does more than just make fire alarms last longer and perform better over time. It's actually a must for businesses operating in places where dust, moisture, or temperature extremes are regular concerns.

Putting explosion proof detectors together with fire alarm control panels makes all the difference when it comes to quick emergency responses. When these detectors can talk directly to central control panels, they speed things up considerably when there's a potential hazard situation. Most industrial sites need this compatibility across different alarm systems because it creates a much better safety net. Real time monitoring becomes possible, which helps manage risks before they get out of hand. Industry data shows that companies who integrated their detection systems saw response times drop by around 30% during actual incidents. Of course results vary depending on how well everything was installed, but the general trend points clearly towards improved safety outcomes for facilities making this investment in integrated protection solutions.

Petrochemical refineries pose serious dangers because they're filled with explosive vapors, which means special detection tech is absolutely necessary. Safety comes first in these kinds of places since something as small as a spark can cause massive destruction. Heat detectors designed for explosions help stop fires before they start, especially around where chemicals are stored. Industry reports show these systems work really well at reducing risk, which explains why most plants have them installed now. As technology keeps improving, it just reinforces how crucial strict safety protocols remain for anyone working in petrochemical operations.

Battery rooms often contain flammable gases, so it's really important to stop any sparks from starting fires. That's why we need those special explosion proof heat detectors installed there. Dusty environments pose similar dangers too. When combustible dust builds up, the risk goes way up. Good detectors can spot when things start getting too hot before something bad happens. Studies have shown time and again that putting these specialized detectors where they belong cuts down on fire accidents significantly. For anyone working around materials that catch fire easily, installing these detectors properly isn't just recommended it's basically part of standard safety procedures now across most industries dealing with potential combustion hazards.

When installed in hazardous areas, HVAC systems really need explosion proof heat detection tech to keep an eye on conditions and stop things from getting too hot. Putting these detection systems into place helps avoid unexpected downtime and keeps workers safe because letting temperatures run wild can wreck equipment pretty quickly. Most industry standards now suggest adding this kind of tech to HVAC setups since it cuts down on safety hazards by a lot. Think of it as insurance for factories and plants that want to keep running smoothly without putting staff at risk. The money spent on proper heat monitoring pays off when accidents are prevented before they happen.

Getting familiar with zoning classifications matters a lot when it comes to setting up explosion proof heat detectors properly in places where there's danger of explosions. The zones - Zone 0, Zone 1, and Zone 2 - basically tell us how much exposure there is to potentially explosive gases in different areas. Zone 0 spots are the worst case scenario since explosive gases hang around all the time there, so equipment needs to be built to handle extreme risks without fail. Zones 1 and 2 aren't quite as bad but still need serious attention to equipment specs because even small mistakes can lead to big problems down the line. Safety agencies make sure companies follow these zone rules strictly. Failure to comply isn't just against regulations, it puts workers at risk and can shut down operations completely if inspections find violations.

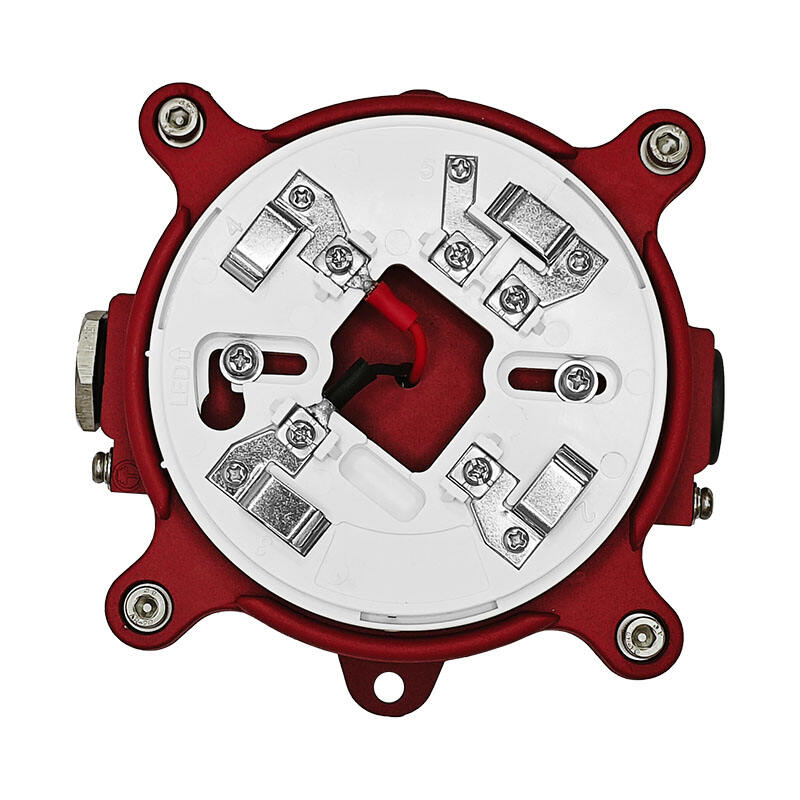

Explosion proof detectors need proper wiring according to strict safety rules because they operate in places where explosions could happen at any moment. Choosing the right wires and making good connections matters a lot since poor wiring can create sparks that might set off an explosion or mess up how the detector works. Organizations like the National Fire Protection Association have created detailed guidelines about this stuff. Following those wiring standards isn't just paperwork either it keeps people safe and makes sure these detectors actually work when needed most in dangerous industrial settings.

Keeping things running smoothly through regular maintenance matters a lot in places where explosions could happen. Maintenance work includes checking if all the equipment still works properly, doing test runs to see if sensors respond correctly, and following set inspection times to catch any signs of wear or possible breakdowns before they become problems. Companies that stick to strict maintenance rules tend to have far fewer accidents, which helps them stay within safety regulations while also making their operations safer overall in these dangerous settings. Looking at industry data shows clearly that sticking to routine maintenance prevents major incidents and keeps detection systems working effectively when they need to most.

Explosion proof heat detectors are built to handle tough conditions, with specs that make them work well in dangerous places. They can operate between -40 degrees Celsius and 85 degrees Celsius, run on 24 volts DC power, and meet IP66 protection requirements against water and dust intrusion. These units stand up to harsh environments including high humidity levels, dirt buildup, and extreme temperature swings. When things get serious, they still send out clear signals when needed most. Industries dealing with flammable materials benefit greatly from these features. For example, oil refineries need equipment that won't fail under pressure while chemical plants require detectors that function reliably despite corrosive substances in the air.

Explosion proof smoke detectors play a vital role in picking up smoke and heat signals within dangerous workspaces, combining two functions into one unit for better overall protection. What makes these detectors stand out is their smart sensing technology that reacts quickly when something's wrong, cutting down on unnecessary alerts without compromising on keeping people safe. We find them particularly important in places where explosions could happen, such as around chemicals or oil refining operations. When looking at different options on the market, companies can compare specs between various models to figure out which ones will work best for their particular setup and requirements.

Copyright © 2026 RISOL TECH LTD All Rights Reserved Privacy policy